IMPROVEMENT

Q1.What is the “iridium” in the IRIDIUM POWER series?

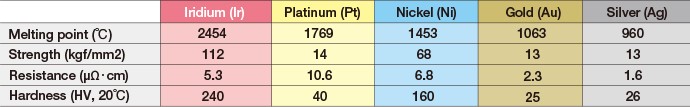

Like platinum, iridium is a noble metal, and is characterized by its extremely high melting point and strength. Because of these properties, it is widely used in cutting-edge technologies in various industries such as the aerospace, medical, and automobile industries. Using a new iridium alloy developed independently by LJK, the IRIDIUM series has achieved an extremely thin center electrode of just 0.4 mm in diameter. Just as it is easier for lightning to strike pointed objects, the thinner the center electrode of a spark plug, the more reliable its sparking will be. It maximizes engine performance and improves mileage and acceleration.

Melting point: Compared with platinum, the melting point is approximately 680°C higher and it has the property of being hard to melt even under high temperature from electrical discharge or combustion.

Strength: Compared with other materials, it has greater material strength and is stable under various operating conditions.

Electricity: Because it has low resistance, even compared with platinum or nickel, it is suitable for spark plug electrodes.

Hardness: It is a tough material that is harder and stronger than other materials.

Q2.How does improved ignitability change things?

It has a wide range of effects, including improved mileage.

Stable idling engine speed

Because the combustion conditions are stable, there is less rotational fluctuation and interruption during idling.

Improved combustion

There is less ignition failure due to misfiring in various operating areas, and the combustion conditions are vastly improved. For this reason, combustion is often improved.

Improved engine performance

Because engine performance is enhanced, acceleration is better than with normal spark plugs.

Cleaner exhaust

CO and CO2 emissions are reduced, producing cleaner exhaust. For those with a high concern for the environment, we especially recommend IRIDIUM POWER.

Q3.Can I use the IRIDIUM POWER series in my own car?

These plugs are compatible with most Japanese and foreign vehicles.

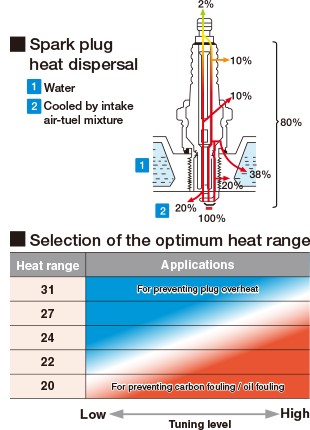

They can be used to replace most spark plugs commonly fitted in Japanese and foreign vehicles. Search the vehicle model compatibility column of the spark plug item number compatibility chart and select an iridium plug suitable for your vehicle. For a normal engine, select a spark plug with the same thermal value as a standard plug, and for a tuned engine, select a spark plug with a thermal value that matches the level of tuning.

Q4.What is the “thermal value” of a spark plug?

It is the degree of dispersion of the heat that a spark plug is subjected to.

The degree of dispersion of the heat that a spark plug is subjected to is known as its thermal value. When that degree is great, it is called a high thermal value (cold type), and when it is small, it is called a low thermal value (hot type). This is influenced by the temperature of the gas within the combustion chamber and the design of the spark plug.

■ Spark plug selection know-how

When the center electrode temperature is kept within approximately 500 to 900°C, a spark plug can perform its function fully. Generally speaking, you should use a plug with a standard thermal value. However, if you mostly just drive short distances at low speeds, which can cause carbon fouling problems, selecting a low thermal value plug can help to prevent such problems.

Q5. What can you tell from the condition of a burnt plug?

|

Appearance |

Condition or type of burning |

Engine or plug condition |

Causes |

Countermeasures |

|

|

The insulator nose turns an ash or reddish-brown color. Electrode wear is minimal. |

The engine runs smoothly on starting and during both high-speed and low-speed driving. |

|

(Normal condition) |

|

|

Brown deposits on the insulator just above the housing |

No influence on spark plug performance |

Caused by electrical stress in the air around the ceramic insulator (not leakage of the spark plug gas, as it is often mistaken for) |

|

|

|

The insulator nose and electrode parts are covered in dry carbon. |

Engine starting worsens, engine turnover is unstable at low speeds, and this can eventually lead to stalling and poor acceleration. |

1. Inappropriate thermal value 2. long-time engine idling or low-speed driving 3. Excessively rich air-fuel mixture 4. Clogged air filter 5. Delayed ignition |

1 & 2: Using a spark plug with a slightly lower thermal value or adjusting engine idling |

|

|

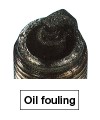

The insulator nose and electrode parts are shiny black from gasoline or oil. |

Engine starting worsens, engine turnover is unstable at low speeds, and this can eventually lead to stalling and poor acceleration. |

1. Oil leakage through the piston due to friction on the piston rings, valve guides, cylinder wall, etc. 2. Excessively rich air-fuel mixture |

1. When running-in a new engine or an engine immediately after an overhaul, spark plugs may become wet until the oil flow control becomes normal, but this can easily be remedied by simply cleaning and reinstalling the plugs. In any other cases, essentially, a complete engine overhaul is required. 2. Adjusting the carburetor |

|

|

The insulator nose is burnt to a bleached white appearance, and the electrodes are also burnt white or to “pale purple color”. Electrodes also rapidly become worn. |

On occasions such as when engaged in continuous high-speed driving, long-time hill climbing, or carrying a lot of luggage, the engine loses power and the vehicle cannot pick up speed. |

1. Inappropriate spark plug thermal value 2. Use of low octane gasoline 3. Ignition timing too early 4. Insufficient cooling 5. Poor air-fuel mixture |

1. Using a spark plug with a slightly higher thermal value 2. Using high octane gasoline 3. Adjusting the ignition timing 4. Checking the cooling system 5. Adjusting the carburetor |

|

|

The electrodes are melted, and in extreme cases, even the insulator nose may be melted. |

As overheating continues, the temperature of the combustion chamber rises rapidly, which can cause damage not only to the spark plug, but also the piston. |

1. Inappropriate spark plug thermal value 2. Use of low octane gasoline 3. Ignition timing too early 4. Insufficient cooling 5. Poor air-fuel mixture |

1. Using a spark plug with a slightly higher thermal value 2. Using high octane gasoline 3. Adjusting the ignition timing 4. Checking the cooling system 5. Adjusting the carburetor |

|

|

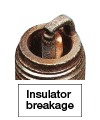

The insulator nose has lengthwise cracking and the insulator shows overheating or has a somewhat large amount of deposits on it. |

On occasions such as when engaged in continuous high-speed driving, long-time hill climbing, or carrying a lot of luggage, the engine loses power and the vehicle cannot pick up speed. |

1. Inappropriate spark plug thermal value 2. Ignition timing too early 3. Malfunctioning cooling system 4. Poor air-fuel mixture |

1. Using a spark plug with a slightly higher thermal value 2. Adjusting the ignition timing 3. Checking the cooling system 4. Adjusting the carburetor |

|

|

The insulator nose is cracked in a ring shape or may have fallen off due to lengthwise cracking. |

Often occurs in tuned cars, usually due to poor setting. Occurs due to sudden acceleration and deceleration or continuous high-speed driving and can lead to piston erosion and turbo damage. |

1. Poor setting during tuning (bad A/F ratio, over-supercharging, knocking, computer modification, etc.) 2. Inappropriate spark plug thermal value 3. Insufficient cooling |

1. Performing proper tuning 2. Selecting a spark plug with thermal value that matches the tuning 3. Checking the cooling system |

|

|

・Ground electrode is broken in the middle or at the base. |

・Ignition failure |

1. Increased stress on the ground electrode due to a high-output, high-torque engine or tuning, modification, etc. 2. Excessive vibration due to poor maintenance, severe operating environment, etc. 3. Insufficient fastening ⇒ excessive vibration due to loose plug |

1. Spark plug selection 2. Engine and vehicle body maintenance |

Q6. Why am I unable to rev the engine immediately after replacing the spark plugs?

We sometimes hear of such cases, but in most cases when we have recalled and inspected such plugs, we have found nothing wrong with them. We assume that the cause is incorrect installation or some other problem relating to the vehicle, but if you have any concerns, please consult with the store where you purchased the product.

Q7. Please explain the methods for spark plug maintenance.

In recent years, iridium plugs with a thin center electrode have become mainstream, and so people used to performing maintenance on conventional spark plugs may find that using a brush to clean off carbon deposits will bend the electrode. Also, adjusting the spark gap when the edges of the electrode have become rounded will not restore the sparking performance to the same level as a new plug. We recommend that you think of the spark plugs as expendable parts and replace them with new ones.

Q8. Does carbon fouling still occur even with the mainstream EFI (electronic fuel injection) of today?

Compared to the age of carburetors, carbon fouling of spark plugs is much rarer, but there are still cases of carbon fouling caused by low engine speed from drivers engaging in extreme eco-driving due to rising gas prices in recent years, or frequent driving in heavy traffic.

Q9. Is there any difference between spark plugs for turbo cars and those for regular cars?

Spark plugs for turbo cars usually have a narrower spark gap and a higher thermal value. This is because a turbo car has a high combustion temperature and a high sparking voltage.

Q10.Does using iridium plugs in an older vehicle make carbon fouling more likely?

This is because iridium spark plugs have superior ignitability to normal spark plugs. In terms of achieving sure combustion, iridium plugs could be said to be more resistant to carbon fouling. However, the predominant causes of carbon fouling are poor fuel adjustment and mismatching of the thermal value and the operating environment, so it is considered important to take countermeasures against these causes.

Q11. How compatible are these spark plugs with hybrid and stop-start vehicles?

Iridium spark plugs are indispensable to hybrid and stop-start vehicles. In particular, they are an essential item in stop-start vehicles, in which startability is especially important.

Q12. Which is more economical: using an iridium plug over a long period, or replacing normal nickel plugs frequently?

For this answer, we will assume an engine with a standard installation of normal nickel spark plugs. Replacing your spark plugs with long-life plugs like IRIDIUM TOUGH will provide a lifespan approximately 5 times that of a normal nickel spark plug and will also improve mileage. The thermal value of an iridium spark plug is higher than that of a normal nickel spark plug, which can provide a benefit in running cost.